Call: 07971670894

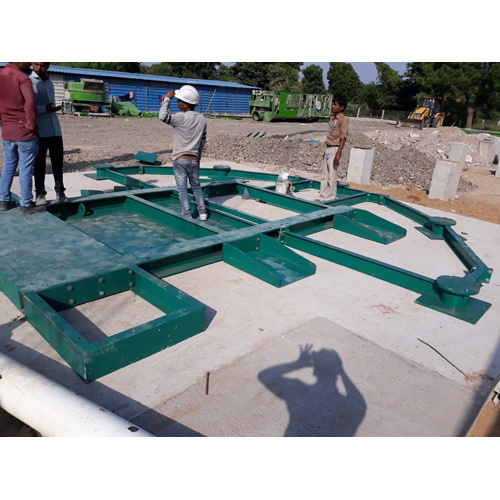

Industrial Skid Fabrication

MOQ : 1 Piece

Industrial Skid Fabrication Specification

- Finish

- Industrial Grade/Painted or Powder Coated

- Type

- Modular Skid Systems

- Usage

- Process Engineering, Chemical, Oil & Gas Industries

- Features

- Pre-piped, Pre-wired, Turnkey Solutions

- Construction

- Stainless Steel/Carbon Steel Options

- Dimensions

- Customized as per Requirement

- Testing

- Hydrostatic/Leak Test as per Standards

Industrial Skid Fabrication Trade Information

- Minimum Order Quantity

- 1 Piece

- Supply Ability

- 100 Pieces Per Month

- Delivery Time

- 7 Days

About Industrial Skid Fabrication

Industrial skid fabrication services specialize in designing and building durable, customized skid systems for various industrial applications. These services include engineering, manufacturing, and assembling skids that integrate equipment like pumps, tanks, and piping into a compact, portable framework. Skid fabrication ensures efficient transportation, installation, and operation of industrial processes, reducing downtime and enhancing productivity. These solutions are tailored to meet specific project requirements, ensuring reliability, safety, and compliance with industry standards. Ideal for sectors like oil and gas, chemical processing, and manufacturing.

Versatile Skid Fabrication Solutions

Our skid systems are perfectly suited for complex industrial processes, integrating equipment and piping on a compact frame. With a modular approach, they deliver flexibility and scalability, allowing for easy installation and future expansion. Both stainless and carbon steel units are customized as needed, ensuring compatibility with your engineering needs.

Stringent Quality Testing and Customization

Every modular skid undergoes rigorous hydrostatic and leak testing, meeting prevalent industry standards to ensure robust, leak-proof operation. Whether powder-coated or painted, our finishes guarantee long-term protection in challenging environments. We adapt our solutions for each client, offering tailored dimensions and configurations for seamless process integration.

FAQ's of Industrial Skid Fabrication:

Q: How are the modular skid systems customized for different industries?

A: Our modular skid systems are designed to be highly adaptable, with customizable dimensions and materials like stainless steel or carbon steel. This ensures each system meets the specific process requirements and environmental conditions of industries such as chemical processing, oil & gas, and general process engineering.Q: What is the fabrication process for your skid systems?

A: The fabrication process begins with detailed engineering based on client specifications. This is followed by precision assembly of structural frames, pre-piping, and wiring. Each skid undergoes stringent hydrostatic or leak tests before being finished with industrial-grade paint or powder coating, ensuring readiness for immediate use.Q: When should a business consider using turnkey skid solutions?

A: Turnkey skid solutions are ideal when a business needs compact, integrated process modules that minimize onsite installation time. They are especially beneficial for projects requiring rapid deployment, streamlined commissioning, and reduced downtime.Q: Where do you export your modular skid systems from India?

A: We export our modular skid systems worldwide, serving clients in various regions including Asia, the Middle East, Africa, Europe, and the Americas. Our manufacturing base in India ensures cost-effective yet high-quality solutions for global operations.Q: What advantages do pre-piped and pre-wired skid systems offer?

A: Pre-piped and pre-wired skids significantly reduce field installation time and errors, as the majority of assembly and checks are completed at our manufacturing site. This approach expedites start-up, simplifies logistics, and supports efficient scaling of process operations.Q: How are your skid systems tested before dispatch?

A: Each unit undergoes rigorous hydrostatic and leak testing according to industry standards. This ensures all connections and components are leak-free and fully functional, guaranteeing safe and reliable performance on site.Q: What benefits do modular skid systems bring to process engineering applications?

A: Modular skid systems offer flexibility, scalability, and reduced project timelines. They allow for parallel construction and testing offsite, enabling quick integration into existing processes. Their turn-key nature helps lower overall project costs and improves operational reliability.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Send Inquiry

Send Inquiry Send Inquiry

Send Inquiry

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese